Kanata Entrepreneur Developing Pre-Cast, Ready to Install Concrete Solutions

IN 2022, AFTER 25 YEARS OF SUCCESS as a residential and commercial contractor for about 2,000 construction homes annually, Gerry Daalder seized a golden opportunity to both expand his business and engage in large scale innovation when he purchased Kustom Pre-Cast Koncrete Ltd.

In addition to his regular contracting work Daalder has, over the past couple of years, spent considerable time and expense modernizing the Kanata-based company. The 58-year old entrepreneur has purchased new equipment, and has patents pending for a new type of concrete that will have myriad applications and benefits.

Upon purchasing the company, Daalder says he addressed the question, “What can we do in the concrete world to help solve my clients’ issues on job sites?” In the process, he adds, “we started to look at different concrete products in an effort to determine ‘what can we do to change the industry?’”

The result has been the engineering of a different concrete with at least 80 per cent less CO2 than regular concrete, thus reducing the company’s carbon footprint by a similar amount, which provides a much stronger, better quality concrete product. Building with 80 percent less carbon also means that instead of having to buy carbon offsets, clients will be able to sell their carbon or be closer to carbon neutral.

“I think the biggest benefit is carbon reduction. There’s nothing else that’s available in the market compared to what we’re doing for concrete in reducing carbon,” Daalder stresses.

“I also think that would be of extreme interest for all levels of government,” he adds.

Another significant advantage is that “with our higher strength, better quality concrete, we should be able to eliminate at least 20 percent of the material that goes into a building.” Moreover, unlike regular concrete, which salt will eat away at it, salt does not affect this product, Daalder says.

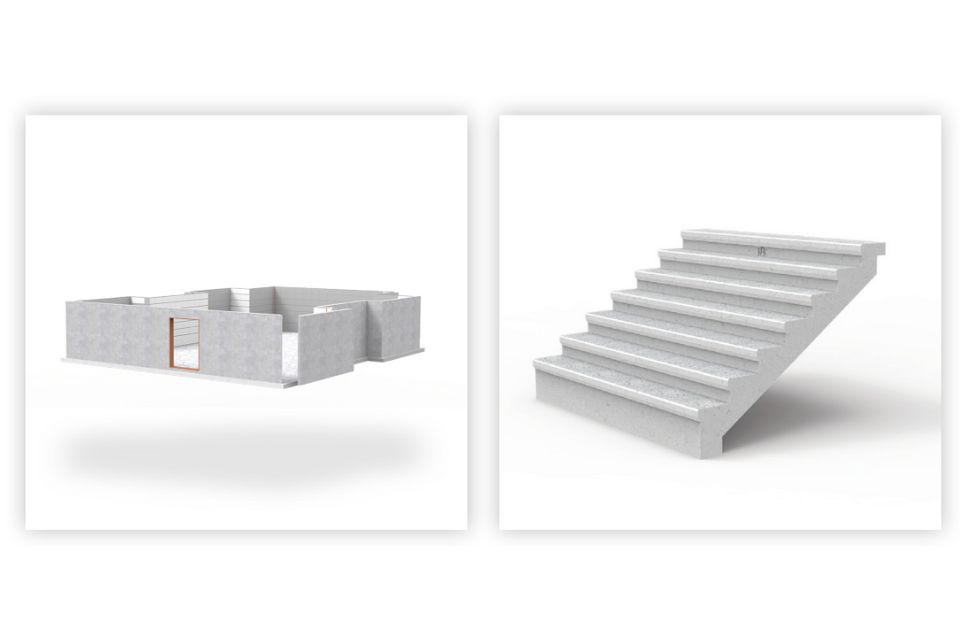

Kustom Precast, which now has 11 employees, has developed ready-forinstall products for both residential and commercial applications, such as porch slabs for homes, and entry stair and stairs for stair wells “with a pleasing high-end anti-slip surface. We’re also working on a modular system that’s almost finalized where we can simply panelize housing where we bring walls that are made out of high strength concrete,” says Daalder.

Those walls come fully insulated, ready for wiring and drywall. When used in multiunits, such as low to mid-rise apartment buildings, it also offers a much higher fire resistance than regular concrete, is very sturdy to reduce noise levels, and is also much less susceptible to physical damage in situations where occupants are irresponsible.

Commercial applications include standardized replacement slabs for broken sidewalks.

“We are extremely excited about our market, which is huge, and letting the world know what we are doing,” Daalder says.